Introduction

Have you ever spent 20 hours on a 3D print, only to find a spaghetti-like mess because of a tiny error halfway through? If you’ve been in the 3D printing game for a while, I’m sure you’re nodding your head. I’ve been there more times than I can count! It’s a soul-crushing experience. But what if I told you that by 2025, those kinds of massive failures are becoming a thing of the past? Seriously. A recent study showed that AI integration can slash print failures by up to 40% and speed up the design process by 50% or more. That’s not just a small step; it’s a giant leap for maker-kind!

We are standing right in the middle of a massive shift in additive manufacturing, and the catalyst is Artificial Intelligence. It’s not just a buzzword anymore; it’s a practical, powerful tool that’s making 3D printing smarter, faster, and more reliable than ever before. Forget the clunky, trial-and-error processes of the past. We’re talking about a future where our machines can think, predict, and even heal themselves. Let’s dive into how this AI revolution is changing everything we thought we knew about turning digital files into physical objects.

From Clunky Prototypes to Flawless Prints: My First Brush with AI in 3D Printing

I remember my first 3D printer like it was yesterday. It was a kit, of course, and getting it calibrated felt like a full-time job. My first “successful” print was a lopsided, wobbly cube that looked nothing like the perfect shape on my screen. For years, that was the reality of desktop 3D printing: endless tinkering, constant supervision, and a whole lot of failed prints that went straight into the recycling bin. You just accepted that a certain percentage of your work would end up as expensive plastic spaghetti. It was just the cost of doing business.

Then, a few years back, I got my hands on a printer with an early-stage AI monitoring system. I was skeptical, to be honest. It sounded too good to be true. The system used a camera and a machine learning algorithm to watch the print as it happened. On my first big print with it, a detailed architectural model, I got an alert on my phone about four hours in. “Potential layer shift detected. Pausing print for inspection.” My heart sank. But when I checked, the AI had caught a minuscule shift, barely visible to my eye, that would have wrecked the entire 15-hour job.

I was able to fix the belt tension and resume the print, and it came out… perfect. That was the moment it clicked for me. This wasn’t a gimmick. The AI wasn’t just watching; it was understanding. It had learned what a good print looks like, and more importantly, it knew the subtle signs of a print starting to go bad. That single experience completely changed my perspective. We were moving from a world where we had to babysit our machines to one where the machines were smart enough to ask for help before things went sideways. It was the end of an era of frustration and the beginning of one of efficiency.

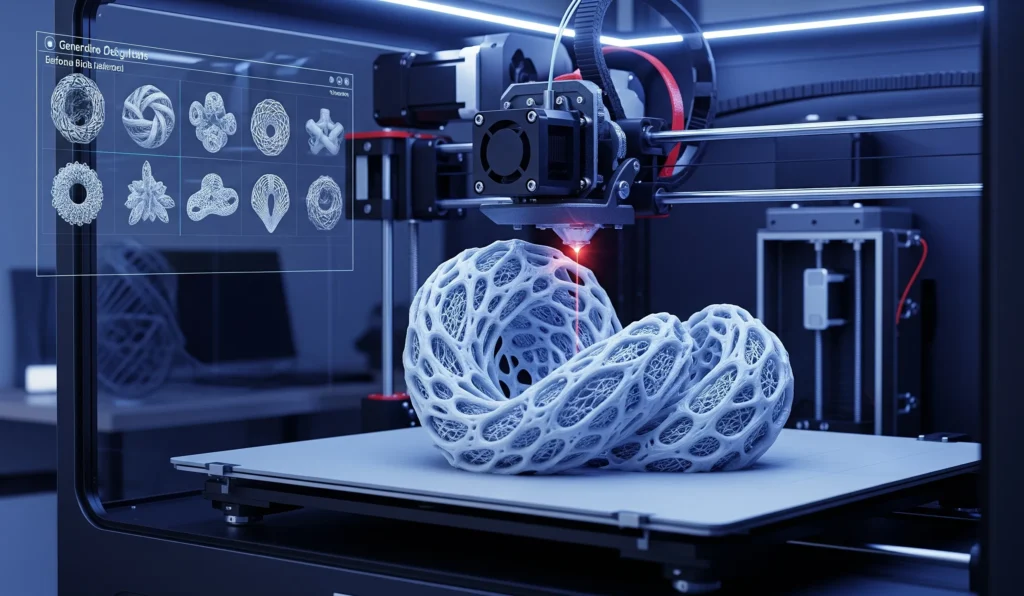

Generative Design: Letting the AI Do the Heavy Lifting

Okay, so if you’ve ever tried to design a complex part from scratch, you know the struggle. You want it to be strong, but also lightweight. It needs to fit perfectly, but also be easy to print. It’s a huge balancing act, and honestly, our human brains are not always the best at it. We tend to fall back on what we know: straight lines, simple angles, and solid blocks. This is where generative design completely blows my mind, and it’s one of the most powerful gifts AI has given to 3D printing.

My first time using a generative design tool, I think it was Autodesk Fusion, which is super popular for this, was for a custom drone frame. I was trying to shave off every possible gram without sacrificing rigidity, a classic engineering headache. Instead of drawing the frame myself, I just gave the AI the rules. I told it: “Here are the four points where the motors mount, here’s where the battery goes, it needs to withstand this much force during a hard landing, and oh yeah, make it as light as you possibly can using this specific PETG material.” Then I hit “go” and went to get a coffee. When I came back, the AI had generated not one, but dozens of design options.

And they looked… alien. They were these beautiful, organic, web-like structures that looked more like bone than anything a human would design. There wasn’t a single straight line or unnecessary bit of material on them. The AI had run thousands of simulations to find the most efficient way to distribute the load, creating a part that was 30% lighter than my best human-designed attempt but just as strong. Printing that part felt like I was printing something from the future. It’s a total game-changer because it frees us from our own design biases and lets us create parts that are truly optimized for their function.

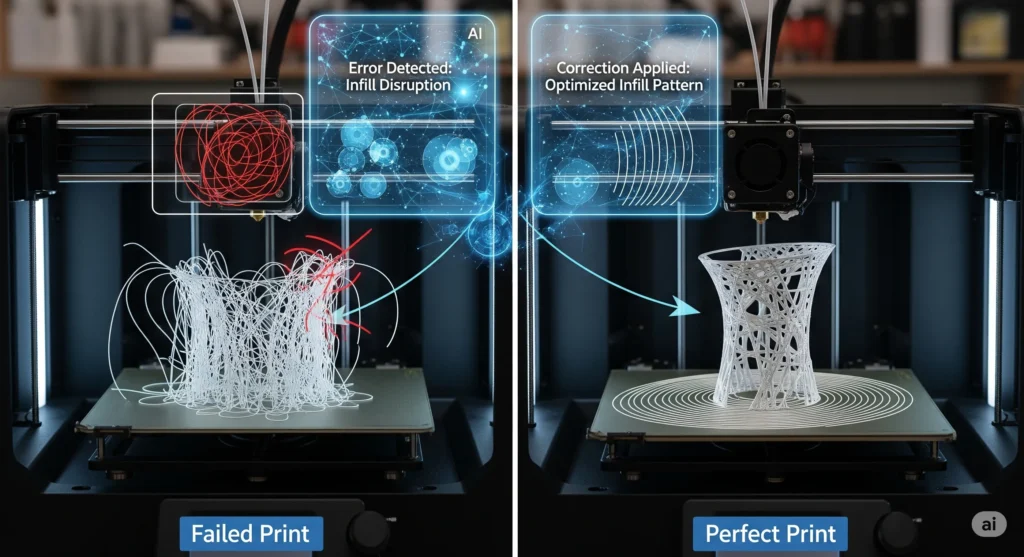

The End of Failed Prints? AI-Powered Real-Time Error Correction

Let’s talk about the single most frustrating thing in 3D printing: the overnight print failure. You set up a 24-hour job, you go to bed dreaming of the awesome thing you’ll have in the morning, and you wake up to a bird’s nest of tangled filament. A tiny nozzle clog or a bit of warping at hour five turned the whole thing into garbage. It’s enough to make you want to throw your printer out the window! For years, the only solution was to watch it like a hawk, which isn’t exactly practical.

This is where AI-powered real-time error correction, like the stuff you see from services like Obico, is making the biggest impact for everyday users. Think of it like a super-smart guardian angel for your printer. Modern systems use cameras and other sensors to not just detect a failure, but to actively correct it on the fly. I was testing a printer with this tech recently, and it was wild to watch. A corner of the print started to lift off the bed, the dreaded warp that has killed so many of my past projects.

Instead of just pausing, the AI immediately adjusted the parameters. It slightly increased the bed temperature in that specific zone and slowed down the print speed for the next few layers over that area to improve adhesion. It basically diagnosed the problem and applied a fix in real-time, without any help from me. Some of the more advanced systems can even detect a partial clog and will automatically increase the filament flow and temperature for a moment to clear it. It’s not foolproof yet, but it’s getting darn close. This technology is turning 3D printers from dumb machines that just follow instructions into smart devices that can problem-solve.

Predictive Maintenance: How AI Keeps Your Printer Humming

If you run a 3D printer long enough, parts will wear out. Belts stretch, bearings get worn, and nozzles degrade. Usually, you find out a part has failed when it causes a catastrophic print failure. Your perfectly smooth walls suddenly get ugly lines (called Z-wobble), or your layers start shifting because a belt finally gave up. It’s a reactive approach; we fix things after they break. But what if your printer could tell you it needed a new part before it failed? That’s the magic of predictive maintenance.

It’s a concept that’s been used in big industrial manufacturing for a while, with companies like 3D Systems implementing it on their high-end machines, but AI is finally bringing it to our desktop machines. The AI listens. It uses the printer’s own motors and sensors to gather data on vibrations, temperatures, and power consumption. It learns the unique “heartbeat” of your specific machine when it’s running perfectly. Over time, as a bearing starts to wear out, it creates a slightly different vibration pattern. A nozzle that’s nearing the end of its life might require a tiny bit more power from the extruder motor to push filament through.

We can’t detect these tiny changes, but the AI can. I had a printer give me a notification that said, “Extruder motor performance has degraded by 3%. Recommend checking for partial clogs or nozzle wear.” I thought it was crazy, the prints still looked fine! But sure enough, when I took a look with a magnifying glass, the nozzle opening was slightly deformed from use. I swapped in a new one, and the notification went away. That simple heads-up prevented who-knows-how-many future failures and saved me a ton of troubleshooting headaches. It’s like having a mechanic who calls you before your car breaks down.

Smarter Slicing and Material Science: The Nitty-Gritty of AI Optimization

When you get down to it, a great 3D print is all about the G-code, the thousands of lines of instructions that tell the printer head exactly where to move. The software that generates this code is called a slicer, and for the longest time, it’s been a very manual process. You’d spend hours tweaking dozens of settings, trying to find the perfect balance of speed, strength, and quality. It was more of an art than a science. AI is turning that art into a data-driven science.

Modern slicers, like OrcaSlicer or Bambu Studio, are getting so smart they feel like AI. They can analyze a 3D model and automatically optimize the print settings. For example, instead of using the same infill pattern for the whole part, the AI can identify areas that will be under high stress and make the infill denser there, while using a lighter, faster infill for non-critical sections. This saves a ton of time and material without sacrificing strength where it matters. It can even orient the part on the build plate automatically for the best combination of strength and minimal support material. It takes so much of the guesswork out of the equation.

This extends to materials, too. Every roll of filament is slightly different, even from the same manufacturer. An AI-equipped printer can run a quick calibration print with a new spool and automatically fine-tune the temperature, flow rate, and cooling settings to match that specific material’s properties. It’s building a unique profile on the fly. This means you get better results, more consistently, without having to print a dozen temperature towers every time you open a new box of filament. It’s a subtle but incredibly powerful improvement that boosts efficiency on every single print.

Conclusion

So, is AI going to take over 3D printing and make our skills obsolete? Absolutely not! What I’ve learned over the past couple of years is that AI is not a replacement for the user; it’s the ultimate assistant. It’s the co-pilot that handles the tedious, repetitive, and error-prone tasks, freeing us up to focus on what really matters: creativity and innovation. It takes the guesswork out of design, watches for errors while we sleep, and keeps our machines running in peak condition. It’s making 3D printing more accessible for beginners and infinitely more powerful for experts.

The revolution is here, and it’s happening right on our desktops. We’re just scratching the surface of what’s possible when you combine additive manufacturing with machine learning. So, embrace the change! Don’t be afraid to let the AI do some of the heavy lifting. The time you save on failed prints and endless tinkering is time you can spend designing the next great thing.

I’d love to hear your thoughts! Have you used any of these AI tools with your 3D printer? Share your own experiences or tips in the comments below!