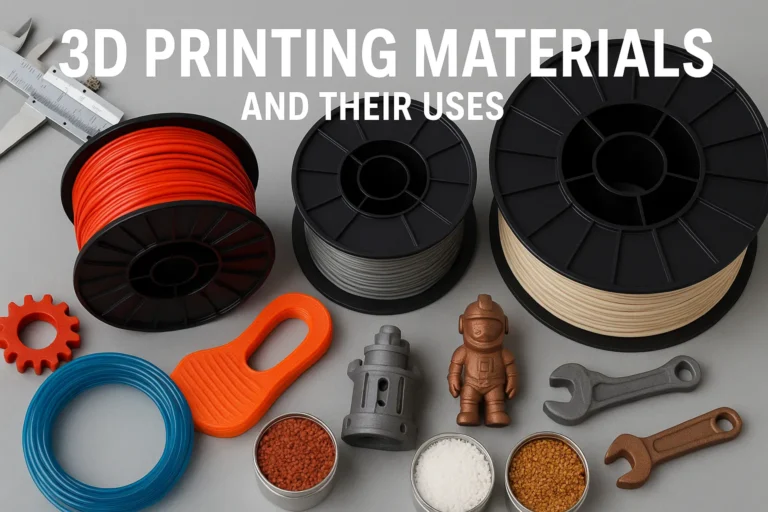

3D printing materials are the lifeblood of additive manufacturing. Whether you’re prototyping a new product, customizing a tool, or crafting intricate art, the choice of material can make or break your design. From biodegradable filaments to aerospace-grade metals, the variety is astonishing. And guess what? The future holds even more promise.

So, if you’re confused about whether to go with PLA, ABS, or something exotic like PEEK or Inconel, you’re in the right place. This guide covers the strengths, weaknesses, and real-world applications of over 30 essential 3D printing materials in 2025 and beyond.

Introduction to 3D Printing Materials

The evolution of 3D printing has come a long way since its inception in the 1980s. Initially limited to plastic prototypes, it now encompasses metals, ceramics, and bio-materials. As 3D printers have become more accessible, so too has the range of materials available for hobbyists, educators, engineers, and manufacturers.

Basics of Material Science in 3D Printing

- Tensile Strength: Determines how much pulling force a material can handle.

- Flexural Modulus: Indicates rigidity or stiffness.

- Heat Deflection Temperature (HDT): Critical for parts exposed to high heat.

- Elongation at Break: Tells you how flexible a material is.

Thermoplastics for 3D Printing

Polylactic Acid (PLA)

PLA is the darling of desktop 3D printing. Why? It’s biodegradable, user-friendly, and prints at lower temperatures. However, its low heat resistance and brittleness mean it’s not suitable for mechanical parts.

Acrylonitrile Butadiene Styrene (ABS)

ABS is tougher and more heat-resistant than PLA. It’s widely used in automotive and consumer goods. The catch? It emits fumes and needs a heated bed to avoid warping.

PETG (Polyethylene Terephthalate Glycol)

PETG combines the ease of PLA with the strength of ABS. It’s food-safe, moisture-resistant, and fairly easy to print.

Nylon (Polyamide)

Strong, flexible, and abrasion-resistant, Nylon is ideal for mechanical parts. However, it’s hygroscopic—meaning it absorbs moisture—so storage is key.

TPU and TPE (Flexible Materials)

If stretch is what you need, look no further. TPU and TPE offer rubber-like elasticity, making them great for wearables and flexible hinges.

Engineering-Grade Plastics

Polycarbonate (PC)

With exceptional impact strength and thermal resistance, PC is used in industrial and engineering applications. It’s not easy to print, but the result is worth it.

PEEK (Polyether Ether Ketone)

PEEK is the holy grail for high-performance applications. It withstands high temperatures and chemical exposure.

ULTEM (PEI)

ULTEM offers high strength and excellent flame resistance. It’s used in medical and aerospace environments.

Resins for SLA/DLP Printing

Standard Resin

Ideal for smooth, detailed prints, but not known for strength. Excellent for concept modeling and miniatures.

Tough Resin

Engineered to withstand stress and impact, tough resins mimic the strength of ABS.

Flexible Resin

These resins simulate the feel and behavior of rubber. They’re perfect for ergonomic and soft-touch parts.

Dental and Medical-Grade Resins

Biocompatible and safe for prolonged skin contact, these resins are FDA-approved in many cases.

Castable Resin for Jewelry

Burns out cleanly during the casting process. Perfect for intricate, high-resolution jewelry design.

Metal 3D Printing Materials

Stainless Steel

Known for strength and corrosion resistance, stainless steel is common in both industrial and medical fields.

Aluminum

Lightweight, durable, and corrosion-resistant. Great for transportation industries.

Titanium

Titanium boasts excellent strength-to-weight ratio and biocompatibility.

Inconel

An alloy known for heat and oxidation resistance. Perfect for extreme environments.

Composite and Filled Filaments

- Carbon Fiber-Filled: Strong, stiff, and lightweight—perfect for automotive and aerospace.

- Glass Fiber-Filled: Durable and stiff, best for mechanical strength.

- Wood-Filled: PLA mixed with wood for aesthetic appeal in art and decoration.

- Metal-Filled: Adds weight and metallic sheen to artistic prints.

Eco-Friendly and Recycled Materials

PLA blends and recycled PETG are gaining traction. They’re affordable, perform well, and reduce environmental impact.

Choosing the Right 3D Printing Material

- What is the application?

- Does it require strength or flexibility?

- Is appearance important?

- What is your budget?

Material Comparison Table

| Material | Strength | Flexibility | Heat Resistance | Cost | Use |

|---|---|---|---|---|---|

| PLA | Medium | Low | Low | Low | Educational |

| ABS | High | Medium | Medium | Low | Functional |

| PETG | High | Medium | Medium | Medium | Food Safe |

| Nylon | High | High | Medium | Medium | Engineering |

| PEEK | Very High | Medium | High | Very High | Aerospace |

Application-Based Material Guide

- Education: PLA, PETG

- Engineering: ABS, Nylon, Carbon Fiber

- Jewelry: Castable resin

- Medical: PEEK, Titanium, Biocompatible Resin

Innovations in 3D Printing Materials

Exciting developments include:

- Self-healing materials

- Conductive filaments

- Graphene-enhanced polymers

FAQs About 3D Printing Materials

What’s the easiest material to start with? PLA is ideal for beginners due to its ease of use and affordability.

Can I 3D print metal at home? Metal printing typically requires industrial-grade equipment, not suitable for home use.

Is PETG safe for food use? Yes, PETG is one of the few food-safe filaments.

Which material is the strongest? PEEK and carbon fiber composites top the list for strength.

How do I store hygroscopic materials? Use airtight containers with desiccants to prevent moisture absorption.

Is resin printing better than filament? It depends on your goal—resin offers more detail, while filament is more versatile and cost-effective.

Conclusion

Understanding 3D printing materials is crucial to unlocking the full potential of your printer. Whether you’re crafting a prototype, building a model, or engineering a functional part, the right material makes all the difference. Choose wisely, experiment often, and keep learning—because the future of 3D printing is as flexible as the materials it prints with.

3 Comments

Pingback: Top 30 Powerful Insights About Plastic Molding in 2025

Pingback: FDM vs SLA: Top 10 Brutally Honest Differences You Must Know

Pingback: What Is the GD&T Full Form? Discover the Meaning, Importance & Usage in Engineering Design